Categories

Categories

Brands

Brands

Vibration Testers Increase Productivity

Posted by on

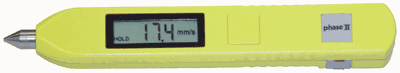

Vibration is present in most, if not all, machinery in industry. It can be used as an indicator of a machine operating under normal or acceptable conditions and used as an indicator that something is going awry; such as a worn bearing or shaft misalignment. Identifying a problem before it gets out of hand is the key to reducing costly repairs and avoiding excessive downtime. A small investment in a vibration tester for use in a preventive maintenance program could prove to be a wise move when the cost savings are realized.

Bob owns a mill in a small Pennsylvania town. He was losing a tremendous amount of money from lost productivity due to machinery breakdowns. He met with his maintenance supervisor and together they designed a plan to reduce downtime by implementing a method of identifying developing problems. Regular preventive maintenance checks were performed at key locations throughout the plant. Vibration readings were recorded and monitored for any changes. When there was a change, such as an increase in vibration readings on a main bearing that showed it was approaching a danger of failure, parts were ordered and bearing replacement was scheduled for a time that would not affect production.

Loading... Please wait...

Loading... Please wait...